HC-200 Utilities

| Inlet Water Flow | 600 LPM – 150 GPM |

| Inlet Water Pressure (required) | 80 PSI Minimum |

| Power Requirement | 575 – 460 VAC |

| Polymer Consumption | 1050 Kg/day @ .5% Concentration |

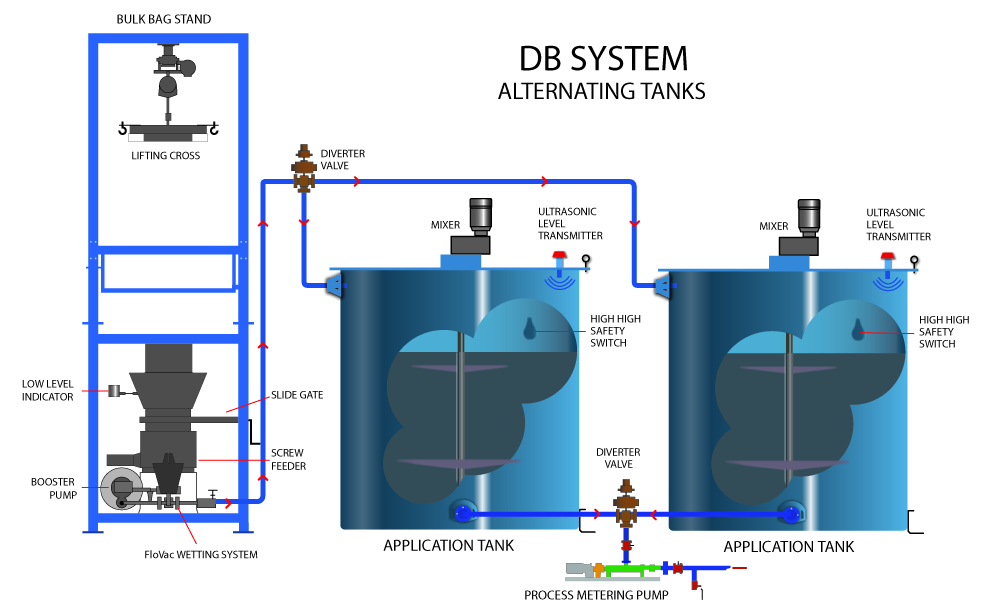

| w / Alternating Tank Configuration * AT | 1500 kg/d Yield |

| PLC Standard | Allen Bradley MicroLogix |

| HMI Standard | Allen Bradley PanelView Plus |

HC-100 Utilities

| Inlet Water Flow | 375 LPM – 100 GPM |

| Inlet Water Pressure (required) | 80 PSI Minimum |

| Power Requirement | 460/575 VAC |

| Polymer Consumption | 700 Kg/day @ .5% Concentration |

| w / Alternating Tank Configuration * AT | 1200 kg/d Yield |

| PLC Standard | Allen Bradley MicroLogix |

| HMI Standard | Allen Bradley PanelView Plus |

Consistent and accurate feeding is critical for industrial and municipal large volume polymer applications. Our designs include a single feed and conditioning screw in all our HC Series Systems volumetric feeders. Hoppers also include a safety screen, a vibrator pad (vibrator optional) hermetically sealed knife gate isolation valve, dust collection hookups and an access hatch with viewing window with a heavy duty locking mechanism.

HC-200

Tank Sizing w/Standard Transfer Pump

| Polymer Usage/Day | Suggested Mix Tank Size (Working Volume) | Std. Transfer Rate |

|---|

| KG’s | Liters | L/Min |

| 325 | 5m3 | 600 |

| 500 | 10m3 | 600 |

| 750 | 15m3 | 600 |

| 900 | 20m3 | 600 |

| 1000 | 25m3 | 600 |

| 1050 | 30m3 | 600 |

| 1250 | *25m3/AT | |

| 1500 | *30m3/AT | |

* Recommended 90-minute mix time.

HC-100

Tank Sizing w/Standard Transfer Pump

| Polymer Usage/Day | Suggested Mix Tank Size (Working Volume) | Std. Transfer Rate |

|---|

| KG’s | Liters | L/Min |

| 300 | 5m3 | 375 |

| 500 | 10m3 | 375 |

| 600 | 15m3 | 375 |

| 700 | 20m3 | 375 |

| 750 | 25m3 | 375 |

| 1125 | *25m3/AT | |

| 1200 | *30m3/AT |